Signage, as a medium, is to express our brand culture and grab customers’ attention. The look for signs will determine how fast people can remember and trust you.

Design is the first step to starting our business signs, how to pick the best colors for advertising signs is essential to create the greatest eye-catching for customers. In this article, we won’t talk more about the color theory, we discuss how to paint and finish the signs.

There are some tips to be considered when we want to get the perfect paints and finishes for business signs, such as the factors before doing painting, the paint method/steps, and the paint finish on the surface you want to get.

Tips before doing spray painting and finishing

Paint is a mixture of pigmented liquid, liquefiable, or solid mastic composition, after application to a substrate in a thin layer, converts to a solid film, which is used for decoration or protection of the signage.(https://en.wikipedia.org/wiki/Painting#Spray_paint)

Veteran spray painter for signs

A perfect painting depends on the construction technical and rich experience of the painter. Firstly we should be familiar with the whole production process of the sign and have hands-on experience with spray paint.

Will your signs be installed indoors or outdoor?

Different substrates of signs will use different primer paint, also different between indoor and outdoor. The weather conditions determine the different characteristics of the paint too.

What are the materials of signs you will make?

Different paints have different adsorption capacities in different substrates. Metal materials need to polish before spraying, but acrylic does not need this step after peeling off the protective films. The aging bake time and temperature after painting are also different.

The visibility of your signs

According to the level of usage, it includes the primer, middle coat, surface coating, etc.

The appearance of the coating film includes gloss, semi-gloss, colored paint; matte, etc.

Different brand cultures can be reflected through different painting methods and surface finishing.

How do you paint on signs?

Spray painting is the main process of surface treatment in the process of making signage. Compared with hand-brush painting, it is high efficiency, uniform paint, and is widely used for large areas of construction.

There are two main purposes of making spray paint for signage, the first one is that make the colors for signs, the second is that formed a protective film on the surface of the sign by spraying various kinds of paint.

The steps to finish your perfect business signs

A. Cutting the material shape of the drawing

B. Surface and edge clean

Surface cleaning includes rust removal, decontamination, oil removal, acid removal, etc. . It can be removed by hand or chemical solution depending on the materials and sign size.

C. Phosphating for metal signs

Phosphating is a chemical and electrochemical reaction to form a phosphate chemical conversion membrane process, the formation of a phosphate conversion membrane called a phosphating membrane. After phosphating, the surface of the metal can protect the base metal from corrosion, and the adhesion and anti-corrosion ability of the film can be improved

D. Putty powder processing

Using the putty powder, it filled the small welding seam, the dent on the metal surface for the defects during the cutting, welding process. The steps are filled with putty powder, dry it, then polish for a flat surface for painting.

E. Spray primed coating

The common is an epoxy primer, it gives the coating good adhesion, excellent chemical stability, and mechanical properties. Epoxy primer can be sprayed twice, the first time completely dry spray, and then spray again.

F. Surface painting

Signage surface paint spray is not a spray finish, a spray paint is too thick, paint is easy to flow, which is commonly known as the flow of hanging. It’s too thin for the paint job. In theory, the number of spray paint, the formation of the quality of the paint, comprehensive consideration of efficiency, in general, sign paint spray using two or three spray ways. Each spray should be thin, uniform paint, the spray paint effect is good.

G. High-temperature baking finish

There are mainly two kinds of baking finish, one is low-temperature baking, the temperature is 140 °C ~ 180 °C, the other is high-temperature baking, the temperature is 280 °C ~ 400 °C.

Before baking, it should clean the dust on the sign surface, the characteristics of these signs will be heat resistance, wet resistance, weather resistance, and corrosion resistance.

FAQ for painting

- Water spots. The main reasons are the high viscosity of the paint, short drying time, long-distance between the spray gun and the surface, spraying time, and paint thickness.

- Uneven color. The pressure of the spray gun is too high or too low during the painting process.

- White coating. High humidity in the paint room or the paint and thinner contains water or volatilize too quickly

Paint finishes

The different paint finishes will be visible on a painted surface by the reflection of how shiny or glossy the reflect light.

The common paint finish on the signs is Gloss, Semi-Gloss, Satin, and Matt. The difference between them is the amount of light reflected, Gloss has the highest sheen, while Matte finish has very little or no sheen.

For ADA Braille signs, it requires a non-glare finish and a high contrast ratio, per chapter §703.5.1. so the sign background and content should be in contrasting colors, that is mean an ADA sign should have a light background and dark characters, or dark background and light characters, and the most common to use for painting finish is semi-gloss or Matt.

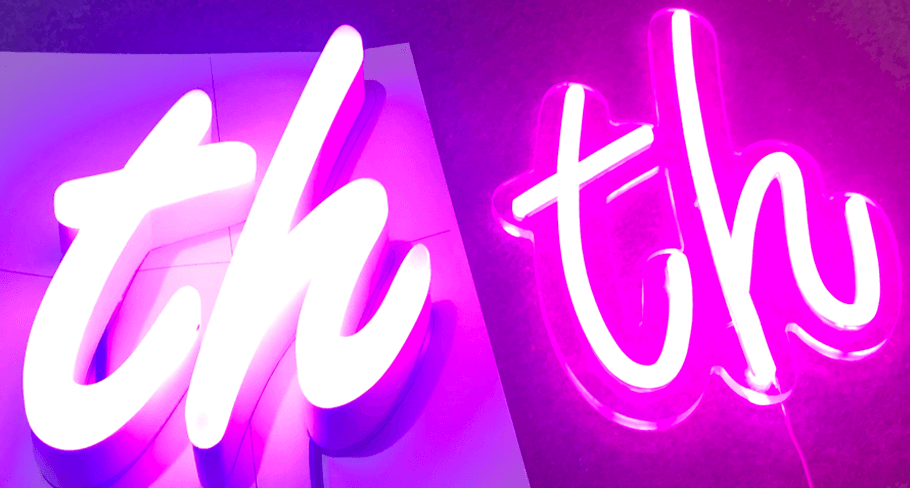

For channel letters, it usually uses the satin finish or semi-gloss to ensure the sign face lights in color at night.

What can FT signage provide for your business signs?

In house spray painting lab, FT signage can spray paint any of your signs whether it will be 3D channel letters, blade signs, lightbox, pylon sign,s and many more…

Our painters are factory-trained and certified. We cleaned and dried the air before entering the painting lab and do it again before painting, and have strict quality control for the primer coating and surface painting.

The goal of every sign is to be noticed, and FT signage is your reliable choice to make your business signs stand out.