When related to 3D effective metal plaques, the following three types are commonly used

1)Relief plaques

2) Casting plaques

3) Etching plaques

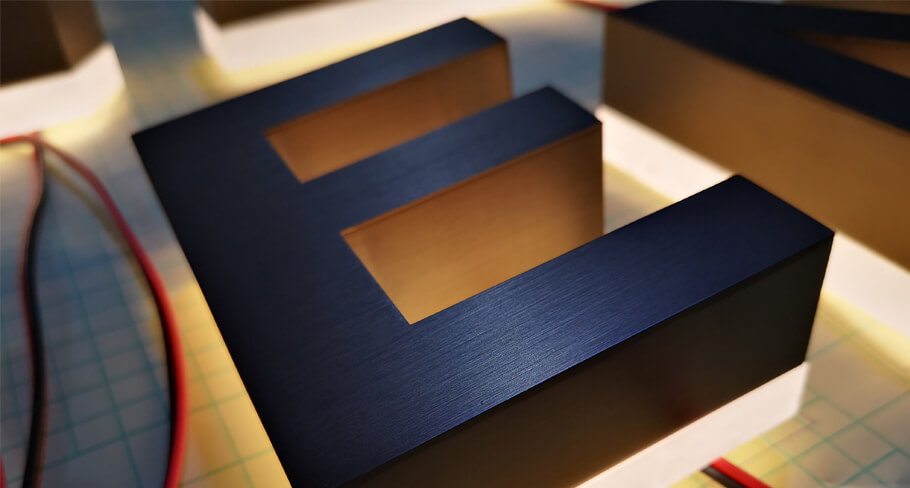

Relief plaques are produced using the CNC router milling out the concave and convex text or image on the solid metal sheet. We can achieve a raised copy and detailed image, which give an enduring plate for signage, dedications, etc. It is also called Tooled Plaques.

Casting plaques is an aging process that results from pouring molten metal into a mold of sand or clay; once cooled, the mold of sand is broken apart, and the metal then hardens to become the framework.

Etching plaques are created by a chemical etching process and text or image into a metal sheet. The graphic and text options include a recessed effect which is recessed text, a graphic with paint filled in, and raised effect, which is raised text or graphics with a painted background, leaving the text or graphics in the alloy color.

The difference between relief plaques, cast plaques and Etching plaques

They are in all-metal, one-piece construction, and 3D effect with raised text, graphics or elements.

Relief plaques benefits

- Faster delivery time, no need to make the mold

- Thinner depths ⅛” and ¼” available

- Available for more detailed letters, logos

- Maximum plaque sizes 84″ x 40″

- Braille is available

- Lower carbon footprint than cast products

- The available materials are bronze, aluminum, and acrylic.

Cast plaques benefits

- Providing a 3D traditional look and finish

- Greater depths than tooled relief plaques and etched signs reach ¼”-1” thick.

- Larger dimension plaque

- Used to create depths logos, emblems, borders, and the largest bas relief casting

- The ideal materials are bronze, aluminum, and stainless steel

Etched plaques benefits

- Etched signs can be made on metal thinner than ¼”. 1 mm is available.

- The depths of text are not as deep as cast plaques.

- Recessed or raised graphics or text

- For raised graphics, there are stroke and artwork limitations

- Ideal materials are brass, bronze, or stainless steel

| Relief plaques (Tooled Plaques) | Etching plaques | Cast plaques | |

| Available materials | Bronze, Brass, Aluminum,Acrylic | Stainless steel, Aluminum,Bronze | Bronze ,aluminum, stainless steel |

| Surface Finish | Classical looks and finish | Precision or Complex line text or graphics | Classical looks and finish |

| Borders | Typically raised border | Often created without a border | Typically raised border |

| Depths of recessed areas | Down to 1/4″ | Maximum 0.1″ | Detail depths up to 1″ |

| Strokes | Depends on router precision | For raised graphics, there are stroke and artwork limitations | Lettering can be made small |

| Size | Maximum plaque sizes based on the cnc machine | Maximum plaque sizes due to substrates size limitations | Larger possible plaque sizes |

| Substrate thickness | 1/8″ think minimum | Thinner to 1/16″ | 1/4″,1/8″ are common |

| Advantage | Better for recessed detail in copy and logos.can include Braille, detailed art, logos, borders and letters | Multi-color paint fill | Traditional looking,great depths and larger size plaques |

| Product time | Fast production time | Fastest turnaround time | slow, need to make mold first |

Takeaway

FT Signage specializes in custom-made plaques. At our plant, we mainly make relief plaques and etched plaques. Welcome to take advantage of our custom metal plaques supply service, and discuss further with us today.

Available options:

- Custom materials and size

- Custom traditional finish and brushed finish

- Large selection of colors and styles

- Custom shapes and corners

- Free layout

- Standard hardware mounting is provided, and installation instructions are available

- Free samples for trail orders

- DHL door to door delivery

- 15-20 days turnaround time upon the order quantity