Electroplating and Anodizing are standard for metal signage surface finishing. Aluminum and stainless steel are the most commonly used materials for metal signs. We know that electroplating is usually for stainless steel, while anodizing is for aluminum.

Can aluminum be electroplated? The answer is yes, but it is much more challenging to electroplate on aluminum than on stainless steel and copper.

To clarify this question, we should know the concepts of electroplating and anodizing.

Both anodizing and electroplating require electricity, but there are essential differences between them.

What is electroplating?

Electroplating attaches a metal coating/layer to the metal’s surface using the electrolysis principle.

Different from anodizing, the material to be plating is used as a cathode, and the coating metal is energized as an anode. Anode metal ions move towards the cathode through the electric charge and deposit on the material to be plated at the cathode.

Electroplating is suitable for the surface treatment of various metals and non-metals. All kinds of metals and non-metals can be electroplated as long as they undergo proper surface treatment. Even if it’s a thin leaf, it can be electroplated as long as it is appropriately treated.

The more common coating/layer metals are gold, silver, copper, nickel, zinc, etc.

What is anodizing?

Anodizing is the creation of oxide film on the surface; it is to use the oxidized metal itself as the anode. It conducts electrolytic oxidation through a low-voltage direct current so that a thick oxide film is formed on the material’s surface, and this oxide film is the oxide of its metal.

Not all metals are suitable for anodizing, but metal alloys and aluminum are widely used in anodizing.

Why is it challenging to electroplate on aluminum?

Compared with steel and copper, electroplating on aluminum is not easy. The reasons are that,

- Aluminum is an active metal. It is easy to form an oxide film on the surface. Even if we take measures to remove it, a new oxide film will be created immediately, which results in a poor plating finish.

- Secondly, the electrode potential of aluminum is meager, and the metal to be plated is easily replaced in the electrolyte, which also causes poor adhesion of the plating layer.

- Thirdly, aluminum is an amphoteric metal and is not stable and corroded in acidic or alkaline solutions.

How to work electroplating on aluminum?

We need to consider the following aspects to achieve a good adhesion coating on aluminum.

Increase surface adhesion

Attaches higher adhesive and unique structure of artificial oxide film, such as phosphoric acid anodization;

Combine the appropriate pretreatment and direct electroplating in a special tank, aluminum will not produce a displacement reaction in this tank, and the coating has good adhesion.

There are many sand holes on the surface when the aluminum alloy is die-casting, which can easily absorb the hydrogen. Therefore, adding anode electrolysis to remove oil when degreasing is recommended to strip off the contaminants hidden in the sand holes as much as possible and peel off the extra hydrogen, strengthening the adhesion.

Prevent or slow down the oxidative process

After removing the natural oxide film, prevent it from forming the film again before electroplating, such as immersion plating, hydrochloric acid etching;

For aluminum alloys, it cannot be directly electroplated. We need to attach an intermediate layer before plating metal coating.

The closest metal of the aluminum alloy lattice is mainly zinc or zinc-nickel alloy layers, so aluminum alloys must be treated with zinc immersion before electroplating. A dense thin zinc layer is deposited on the clean surface before electroplating.

Strictly regulating the operations of each process

Select suitable materials for plating. Only two aluminum alloy materials are ideal for electroplating: pure industrial aluminum and silicon-containing magnesium-aluminum alloy.

Monitoring each step, especially controlling and preventing in advance, are the measures to get the excellent quality of the adhesion layer.

Takeaway

Now, we know that electroplating aluminum is not easy. It takes more time than electroplating stainless steel and other materials.

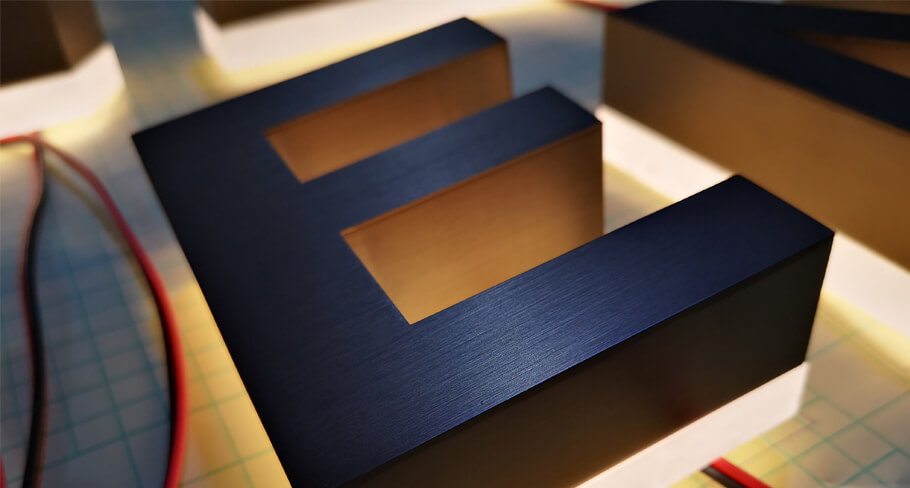

FT Signage specializes in custom-made LED signage and wayfinding plaques made of aluminum, stainless steel, acrylic, brass, etc. Various electroplating colors are available for cut-out letters, illuminated letters, and plaques.

Contact us today for more information if you have additional questions about custom plating or anodizing signage.