Aluminum ADA plaques are a key element in creating spaces that are both professional and accessible.

Designed to meet the requirements of the Americans with Disabilities Act (ADA), these signs provide tactile lettering and Braille for individuals with visual impairments. They not only ensure regulatory compliance but also enhance navigation and usability in public and commercial buildings.

This article explores the benefits of aluminum ADA plaques, common manufacturing methods, and key factors to consider when placing an order.

What Are Aluminum Tactile & Braille Signs?

Aluminum ADA plaques are specially designed signage products manufactured in compliance with ADA guidelines. They feature raised characters, tactile elements, and Braille to guide users effectively. Unlike standard printed metal plaques, these signs are designed with accessibility and usability in mind.

Key characteristics include:

- Raised text and numbers for tactile reading

- Grade 2 Braille for accessibility

- Non-glare finishes for improved visibility

- High-contrast designs for clarity

Common examples include:

- Room identification signs (room numbers, meeting rooms, offices)

- Restroom signs

- Directional signs (wayfinding, exits, elevators)

- Safety and compliance signs

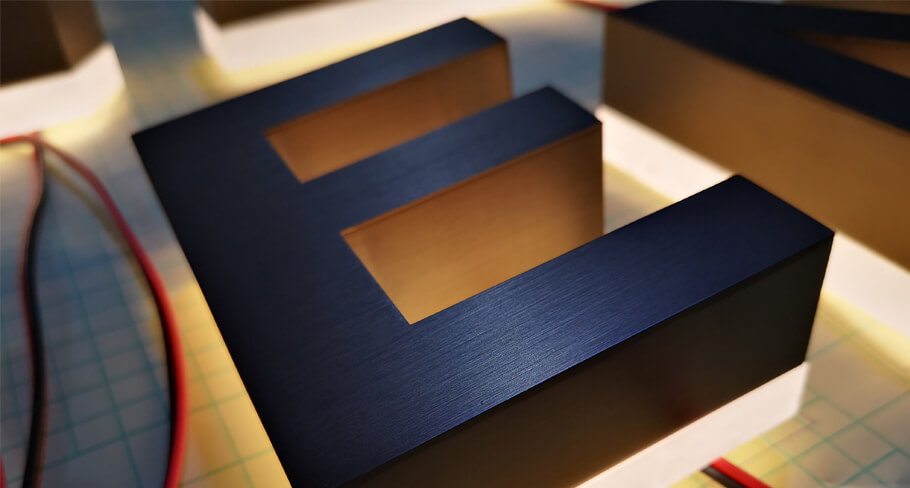

Benefits of Aluminum for ADA Signage

Aluminum offers several advantages when used in ADA-compliant signage:

- Durability: Resistant to corrosion, wear, and weather conditions, suitable for long-term use.

- Professional appearance: Brushed, anodized, or painted finishes create a polished and modern look.

- Design flexibility: Can be cut, engraved, or finished in multiple ways to align with branding requirements.

- Sustainability: Aluminum is a recyclable material, supporting environmentally responsible practices.

- Low Maintenance: Unlike plastic or wood, aluminum signs require minimal upkeep while maintaining a professional appearance over time.

Building on these strengths, aluminum Braille signs have become a trusted choice across many environments. Hospitals and clinics rely on them for safe navigation, while schools and universities use them for accessible classrooms and facilities. Offices add them for compliance and a professional look. Stores, restaurants, hotels, and transport hubs depend on durable aluminum plaques to guide people every day.

Manufacturing Methods

Aluminum ADA plaques can be produced using two primary techniques: the Raster Bead Method and the CNC Engraved One-Piece Raised Method. Both approaches comply with ADA standards but offer different benefits.

1. Applique & Raster Bead Method

- Process: Appliqué and raster ADA signs are made using an engraving machine that drills small holes into the aluminum panel, where rounded acrylic or steel beads are inserted with an automatic tool to form durable, ADA-compliant Braille dots.

- Advantages:

- Efficient production for larger quantities

- Smooth, uniform tactile dots

- Cost-effective for general applications

- Considerations:

- Beads must be precisely inserted to ensure long-term stability

- Slightly less durable in outdoor or high-impact environments

2. Precision tool Engraved & Raised Method

- Process: Braille dots and raised characters are carved directly into the aluminum surface using CNC router milling out.

- Advantages:

- Strong, one-piece construction without separate bead components

- Premium appearance suitable for high-profile projects

- Excellent durability in outdoor and high-traffic areas

- Considerations:

- Higher manufacturing cost

- Longer production time compared to the raster method

Selection guidance: Raster bead plaques are a practical choice for most indoor applications, while CNC-engraved plaques are recommended for high-demand environments where long-term durability and appearance are top priorities.

Buying Guide: What to Consider Before Ordering

When planning to order aluminum tactile and Braille signs, it is essential to consider not only appearance but also long-term performance and compliance. Here are some key points to consider:

Design Considerations

Accessibility laws and building codes play a crucial role in signage. In the United States, ADA-compliant signs are mandatory in many public spaces. To ensure compliance and functionality, the following points should be addressed when specifying aluminum ADA plaques:

- Raised characters: 1/32” pictograms and Grade 2 domed braille dots

- High Contrast colors: Strong visual contrast between characters and background for maximum readability

- Finish: Non-glare surface for clear visibility under different lighting conditions

- Fonts: Clear, sans-serif fonts, a minimum 5/8” height for the tactile characters, and all characters must be uppercase

- Size and spacing: A minimum of 1/8 inch must be maintained between adjacent characters, while the maximum is four times the character stroke width. The spacing between lines of raised text must be between 135% and 170% of the character height, measured baseline to baseline. And the nominal line spacing of Braille cells from center to center of nearest corresponding dots in adjacent lines must be 0.400 inches.

- Mounting height: The baseline of the lowest tactile character is installed at 48–60 inches from the finished floor

Durability Needs

Different environments require different levels of durability.

- Panel Thickness – Outdoor applications usually require thicker aluminum (often 1/8 inch or more) to resist bending, warping, or impact. Indoor settings may use thinner panels but should still ensure structural stability.

- Surface Finish – Powder coating or anodizing protects against scratches, corrosion, and fading, keeping the signs looking professional for years.

- Weather Resistance – For exterior signs, UV protection and moisture resistance are essential to prevent color loss, rust, or deterioration from sun, rain, and snow.

- High-Traffic Durability – In busy locations such as hospitals, schools, or transportation hubs, signs should be built with harder finishes that resist frequent contact and cleaning.

- Long-Term Performance – Regardless of location, durability ensures ADA signs remain legible and reliable, reducing the need for replacements and extra costs.

Reliable Supplier

Selecting the right supplier is a key step when ordering aluminum ADA plaques. A dependable partner should provide:

- Proven Experience – Solid background in ADA-compliant signage and a consistent record of quality.

- Capacity & Lead Time – Sufficient production capability to handle bulk orders and meet deadlines without delays.

- Compliance Assurance – Understanding of ADA and local accessibility codes, with accurate character sizing, spacing, Braille placement, and non-glare finishes.

- Quality Guarantee – Warranties or quality commitments that safeguard your investment and ensure long-term performance.

Take Away

Aluminum ADA plaques are essential for creating spaces that are both professional and accessible. Designed to meet the Americans with Disabilities Act (ADA) standards, these signs feature tactile lettering and Braille to assist individuals with visual impairments, ensuring compliance while enhancing usability in public and commercial buildings.

Whether produced with the raster bead system or Precision tool-engraved, aluminum ADA plaques combine durability with clear, legible communication. By selecting the appropriate manufacturing method, design features, and installation approach, facilities can achieve signage that is fully compliant and visually integrated with their surroundings.

FT Signage offers customized aluminum ADA plaques in a range of finishes and styles to meet any project requirement. Contact us today to discuss your signage needs and discover the best solution for your business.